Sanand, Ahmedabad, Gujarat

- GST NO. : 24CXWPP9877P1ZT

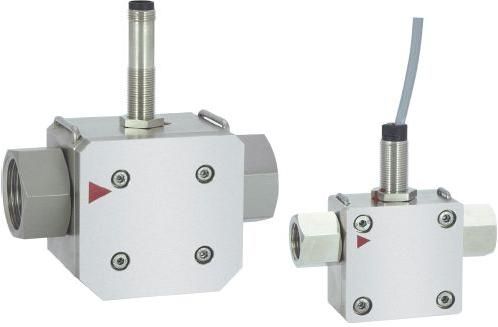

Honsberg Flow Transmitters

Honsberg flow transmitters are commonly used as an essential parameter in several processes. At J V M Engineering we manufacture 100% authentic Honsberg flow transmitters that don’t consist of any moving parts, extra pressure drops, and flow passage sans any projecting parts. Based in Ahmedabad, our range of Honsberg flow transmitters doesn’t get affected by the temperature changes, or changes in electrical conductivity, concentration, viscosity, density.

We engineer Honsberg flow transmitters with the choicest of materials for the chemically aggressive measuring media. Being the pioneers of Honsberg flow transmitters supplier, we design a flow transmitter that is especially perfect for the transport of hydraulic solids. Most importantly, the Honsberg flow transmitters can be operated in both flow directions.

Honsberg Flow Transmitters Suppliers in India

With the advancement of technology and the development of industries, there is a surge in accurate and precise measurements. Our Honsberg flow meters are one of those innovative tools that we design to cater to these requirements. Our persistent development of this machinery has met the advancement of several industries and an ever-rising line of applications.

Each of our Honsberg flow transmitters is used by a variety of industries like the food and beverages, paints, pharmaceutical, chemical, petrochemical, and fuel industries. More so, being the largest Honsberg flow transmitter supplier, our engineers ensure that the design flow meters that can stand resilient to pressure and all types of weather conditions.

The use of Honsberg flow transmitters has a large variety of benefits. Call us to know more about them.

MOQ : 100 Piece

| Business Type | Exporter, Supplier |

| Sensor | Vortex principle |

| Nominal width | DN 8..25 |

| DN 8..25 | Female thread G 1/4..G 1 (others available on request) |

| Pressure resistance | PN 10 bar |

| Media temperature | 0..60°C |

| Ambient temperature | -20..+70°C |

| Supply voltage | 10..30 V DC |

| Current consumption at rest | Approx. 20 mA (without load) |

| Electrical connection | For round plug connector M12x1, 4-pole |

| Ingress protection | IP 67 |

| Conformity | CE |

| Make | Honsberg |

| Download |

Preferred Buyer From

| Location | Worldwide |

Details :

- Flow measurement device using the vortex measurement principle

- High precision

- High stability to excessive flow rates

- No moving parts

- Rapid installation and removal thanks to clamp fastening

- Various connections using building block system

Handling and operation : The vortex flow meter requires a run-in length of 5..10 x D in order to achieve its specified accuracy. If deposits are to be expected, sensor and electronics should not be installed underneath. It should be ensured that the sensor is installed in the direction of the flow arrow. If the sensor is to be cleaned, the clamps should be released, and the device removed (the pipe should be pressure-free for this). It should be ensured during cleaning that the oscillating vortex body is not exposed to impact (in the moulded part there is a sensitive piezo-ceramic sensor, which can break).

Accessories :

- Cable/round plug connector (KB...)

- Counter EEZ-904

- Converter/counter OMNI-TA

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Make | Honsberg |

| Flow Range | From 0.4 to 100 L/min Flow Ranges |

Preferred Buyer From

| Location | Worldwide |

A very versatile reliable flow switch using a dynamic diaphragm made of stainless steel, which covers the whole cross section of the pipe and is deflected by the flow, which is then detected by a sensor.

100 bar High pressure Version AvailableA very versatile reliable flow switch using a dynamic diaphragm made of stainless steel, which covers the whole cross section of the pipe and is deflected by the flow, which is then detected by a sensor.

Features:

- Very fast response time

- High Overload Protection

- High Max Flow

- Low pressure Loss

- Compact Design

- 150c High Temperature Option

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Range | From 0.4 to 100 l/min flow ranges |

| Make | Honsberg |

Preferred Buyer From

| Location | Worldwide |

A very versatile reliable flow switch using a dynamic diaphragm made of stainless steel, which covers the whole cross section of the pipe and is deflected by the flow, which is then detected by a sensor.

100 bar High pressure Version AvailableA very versatile reliable flow switch using a dynamic diaphragm made of stainless steel, which covers the whole cross section of the pipe and is deflected by the flow, which is then detected by a sensor.

Features:

- Very fast response time

- High Overload Protection

- High Max Flow

- Low pressure Loss

- Compact Design

- 150c High Temperature Option

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Make | Honsberg |

| Analog Output | 4..20 mA or 0..10 V |

Preferred Buyer From

| Location | Worldwide |

Features:

- Flow transmitter with display

- For pipe diameters of DN32 or larger

- Plastic version

- Suitable for retrofitting in existing pipelines with tapping clamps

- Two programmable switches

- Selectable units in the display

- Parameter change via rotating ring

- Electronics housing with non-scratch, chemically resistant glass

- Rotatable electronic housing for best reading position

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Sensor | Gearwheel volumeter |

| Nominal width | DN 8..25 |

| Process connection | G 1/4..G 1 |

| Repeatability | ±0.3 % |

| Medium temperature | -25..+80°C optionally -25..+120°C |

| Ambient temperature | -20..+70°C |

| Pressure loss | See upstream page |

| Supply voltage | 18..30 V DC |

| Power consumption | < 1 W |

| Conformity | CE |

| Hysteresis | Adjustable, position of the hysteresis depends on minimum or maximum |

| Electrical connection | For round plug connector M12x1, 5-pole |

| Ingress protection | IP 67 / (IP 68 when oil-filled) |

| Make | Honsberg |

| Download |

Preferred Buyer From

| Location | Worldwide |

Flow Transmitter / Switch OMNI-VHZ :

- Flow sensor using the gearwheel principle

- Suitable for viscous media (oils, emulsions)

- Analog output 4..20 mA or 0..10 V

- Two programmable switches (push-pull)

- Graphical LCD display, backlit (transreflective), can be read in sunlight and in the dark

- Modifiable units in the display

- Programmable parameters via rotatable, removable ring (programming protection)

- Full metal housing with non-scratch, chemically resistant glass

- Rotatable electronic head for best reading position

- Small, compact construction

- Simple installation

Characteristics :

- The VHZ gearwheel flow meter measures the flow by a volumetric principle, in which a pair of gearwheels is moved proportional to the flow rate.

- The movement of the gearwheels is measured through the enclosing housing wall by a sensor. The devices are suitable for viscous, fluid, self-lubricating media, as well as for aqueous fluids such as soaps, pasts, emulsions etc. which have a non-abrasive character. Because of the volumetric functioning principle, the devices are almost completely independent of viscosity.

- The OMNI transducer located on the sensor has a backlit graphics LCD display which is very easy to read, both in the dark and in bright sunlight. The graphics display allows the presentation of measured values and parameters in a clearly understandable form. The measured values are displayed to 4 places, together with their physical unit, which may also be modified by the user. The electronics have an analog output (4..20 mA or 0..10 V) and two switching outputs, which can be used as limit switches for monitoring minimal or maximal, or as two-point controllers.

- The switching outputs are designed as push-pull drivers, and can therefore be used both as PNP and NPN outputs. Exceeding limit values is signalled by a red LED which is visible over a long distance, and by a cleartext in the display. The stainless steel case has a hardened non-scratch mineral glass pane. It is operated by a programming ring fitted with a magnet, so there is no need to open the operating controls housing, and its leakproofness is permanently ensured.

- By turning the ring to right or left, it is simple to modify the parameters (e.g. switching point, hysteresis...). To protect from unintended programming, it can be removed, turned through 180 ° and replaced, or completely removed, thus acting as a key.

Option C : Preset Counter with external reset option, complementary switching outputs and actual value display.

Option C1 : Instantaneous value display with analogue output, pulse-volume output and totalizer

Handling and operation : The VHZ flow measurement device can be installed anywhere in the pipework system. A run-in section is not required. The direction of flow may be freely chosen. It should be ensured that no dirt particles (thread cutting swarf) can get into the flow space, as this could cause the blockage of the gearwheels. It may therefore be necessary to install filters upstream of the flow measurement device (mesh size 30 μm).

Programming :

The annular gap of the programming ring can be turned to positions 1 and 2. The following actions are possible :

- The ring can be removed to act as a key, or turned through 180 ° and replaced to create a programming protector. Operation is by dialog with the display messages, which makes its

- use very simple. Starting from the normal display (present value and unit), if 1 (STEP) is repeatedly selected, then the display shows the following information in this order :

- Display of the parameters, using position 1

- Switching value S1 (switching point 1 in the selected unit)

- Switching characteristic of S1

- MIN = Monitoring of minimum value

- MAX = Monitoring of maximum value

Hysteresis 1 (hysteresis value of S1 in the set unit) - Switching value S2

- Switching characteristic of S2

- Hysteresis 2 Code

- After entering the code 111, further parameters can be defined:

Filter (settling time of the display and output) - Physical unit (Units)

- Output - 0..20 mA or 4..20 mA

0/4 mA (measured value corresponding to 0/4 mA) - 20 mA (measured value corresponding to 20 mA)

- For models with a voltage output, replace 20 mA accordingly with 10 V

- Edit, using position 2 If the currently visible parameter is to be modified :

- Turn the annular gap to position 2, so that a flashing cursor appears which displays the position which can be modified.

- By repeatedly turning to position 2, values are increased; by turning to position 1, the cursor moves to the next digit.

- Leave the parameter by turning to position 1 (until the cursor leaves the row); this accepts the modification.

- If there is no action within 30 seconds, the device returns to the normal display range without accepting the modification.

- The limit switches S1 and S2 can be used to monitor minimal or maximal. With a minimum-switch, falling below the limit value causes a switchover to the alarm state.

- Return to the normal state occurs when the limit value plus the set hysteresis is once more exceeded. With a maximum-switch, exceeding the limit value causes a switchover to the alarm state.

- Return to the normal state occurs when the measured value once more falls below the limit value minus the set hysteresis.The change to the alarm state is indicated by the integrated red

- LED and a cleartext in the display. While in the normal state the switching outputs are at the level of the supply voltage; in the alarm state they are at 0 V, so that a wire break would also display as an alarm state at the signal receiver.

Overload display : Overload of a switching output is detected and indicated on the display ("Check S 1 / S 2"), and the switching output is switched off.

Simulation mode : To simplify commissioning, the sensor provides a simulation mode for the analog output. It is possible to create a programmable value in the range 0..26.0 mA at the output (without modifying the process variable). This allows the wiring run between the sensor and the downstream electronics to be tested during commissioning. This mode is accessed by means of Code 311

Factory settings : After modifying the configuration parameters, it is possible to reset them to the factory settings at any time using Code 989.

Options :

- Counter C (hardware and software option)

- Preset Counter with external reset option, complementary switching

- outputs and actual value display (modified wiring diagram!)

- Counter C1 (software option): Instantaneous value display with analogue output, pulse-volume output and totalizer

Accessories :

- Cable/round plug connector (KB...) see additional information “Accessories”

- Device configurator ECI-1

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Sensor | dynamic diaphragm |

| Nominal width | DN 8..25 |

| Pressure loss | max. 0.5 bar at the end of the metering range |

| Media temperature | 0..+70 °C with high temperature option 0..150 °C |

| Ambient temperature | 0..+70 °C |

| Storage temperature | -20..+80 °C |

| Supply voltage | 18..30 V DC |

| Power consumption | < 1 W |

| Signal output | 4/0..20 mA / max. load 500 Ohm (0/2..10 V available on request) |

| Hysteresis | adjustable, position of the hysteresis depends on minimum or maximum |

| Electrical connection | for round plug connector M12x1, 5-pole |

| Ingress protection | IP 67 / (IP 68 when oil-filled) |

| Conformity | CE |

| Make | Honsberg |

| Download |

Preferred Buyer From

| Location | Worldwide |

Flow Transmitter / Switch OMNI-XF

- Universal flow rate sensor with dynamic diaphragm

- Analog output, two switching outputs

- Clear, easily legible, illuminated LCD display

- Modifiable units in the display

- Designed for industrial use

- Small, compact construction

- Simple installation

Characteristics :

- A thin elastic diaphragm made of stainless steel, which covers the entire flow cross-section, is deflected by the flowing fluid, and thereby pushes against an arched end stop.

- There is a plastic-coated magnet on the diaphragm. When there is a deflection, its magnetic field changes, and this is detected by a sensor outside the area of flow.

- Flexible diaphragm made of stainless steel, with plastic-coated magnet.

- Because the diaphragm only bends, and functions without a bearing, there is almost no frictional effect. The movement therefore occurs practically free of hysteresis, and the test results have very good reproducibility.

- The diaphragm's low bulk results in a short response time. The almost complete covering of the flow cross-section in the neutral position produces very high start-up sensitivity. As soon as the slightest flow exists, the diaphragm is of necessity deflected.

- The evaluation of the entire flow cross-section means that there are no problems when routing pipes. Run-in and run-out sections are not necessary.

- The shaped end stop and the elastic properties of the diaphragm mean that even severe water hammer causes no damage. The low number of medium contact parts guarantees reliable operation and a low tendency to contamination.

- There are flanged connection pieces on the inlet and outlet; these are available in various nominal widths and materials. By removing the four bolts of the flange connection, it is simple to remove the measurement unit for servicing, while the connections remain in the pipework.

- The OMNI transducer located on the sensor has a backlit graphics LCD display which is very easy to read, both in the dark and in bright sunlight. The graphics display allows the presentation of measured values and parameters in a clearly understandable form.

- The measured values are displayed to 4 places, together with their physical unit, which may also be modified by the user. The electronics have an analog output (4..20 mA or 0..10 V) and two switching outputs, which can be used as limit switches for monitoring minimal or maximal, or as two-point controllers. The switching outputs are designed as push-pull drivers, and can therefore be used both as PNP and NPN outputs.

- Exceeding limit values is signalled by a red LED which is visible over a long distance, and by a cleartext in the display. The stainless steel case has a hardened non-scratch mineral glass pane.

- It is operated by a programming ring fitted with a magnet, so there is no need to open the operating controls housing, and its leakproofness is permanently ensured.

- By turning the ring to right or left, it is simple to modify the parameters (e.g. switching point, hysteresis...). To protect from unintended programming, it can be removed, turned through 180 ° and replaced, or completely removed, thus acting as a key.

Option C : Preset Counter with external reset option, complementary switching

outputs and actual value display.

Option C1 : Instantaneous value display with analogue output, pulse-volume

output and totalizer

Options : Through a range of options, the XF system is flexibly adaptable to very varied requirements.

Full metal construction

- The standard version has a plastic body with a pressure resistance of 16 bar. A metalled body (nickelled brass) with a pressure resistance of 100 bar is optionally available. The higher operating pressure requires a combination with metal connection pieces.

- Measurements and switching value settings in the range 1..80 l/min are possible.

High temperature : If the full metal model is fitted with high temperature sensors and a gooseneck, operation at media temperatures up to 150oC is possible.

Note : Operation using the plastic body is also possible at temperatures greater than 70oC. However, it should be noted that this reduces the stability to pressure .

Resistance to backflows :

- With forward flows, the diaphragm pushes against an arched end stop, and is undamaged by flow rates which are significantly higher than the intended metering range, or by water hammer.

- For flows or pressure surges in the reverse direction, in the standard version the diaphragm pushes against a circumferential support ring made of plastic or stainless steel, and almost completely closes the flow cross-section.

- This causes pressure to build up which can damage the diaphragm. In applications where such conditions can arise (e.g. from elastic hoses to the rear of the measuring equipment) the use of the "resistance to backflows" option is recommended.

- Here, the support ring is replaced by another arched end stop made of stainless steel, so that the diaphragm is provided with the same overload and pressure surge resistance in the reverse direction as in the forward direction.

- However, a measurement or setting of switching value in the reverse direction is not possible.

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Sensor | hall element |

| Nominal width | DN 10 (RRH-010) , DN 25 (RRH-025) |

| Pressure resistance | PN 100 bar |

| Medium temperature | 0..100 °C |

| Current consumption | 30 mA |

| Output current | max. 100 mA |

| Electrical connection | cable 2 m or for Round plug connector M12x1, 4-pole |

| Resistant to short circuits | yes |

| Reversal polarity protected | yes |

| Ingress protection | IP 67 |

| Conformity | CE |

| Make | Honsberg |

| Download |

Preferred Buyer From

| Location | Worldwide |

Flow Transmitter RRH :

- Uncomplicated measurement of flow rates

- Metal housing with Hall sensor

- Working pressure up to 100 bar

- Long working life thanks to high quality ceramic axis and special plastic bearing

- Run-in and run-out sections are not necessary.

- Modular construction with various connection systems

- Plug-in and rotatable connections

- Output signal PNP or NPN

- Intrinsically safe behaviour

- Optionally, non-return valve, filter, constant flow rate device in the connections.

Characteristics : The flow meter consists of a spinner which is rotated by the flowing medium. The rotor's rotational speed is proportional to the flow volume per unit time. The rotor is fitted with magnets. A Hall sensor records the rotational speed, which is proportional to the flow rate.

Wiring : Air bubbles affect the measurement results. For filling processes, the valve should be installed behind the sensor. A running up time of approx. 0.5 seconds and a running down time of approx. 3 seconds should be noted.

Handling and operation :

Installation

The Rototron device is installed in the pipework with the aid of the rotatable adapter pieces. If necessary, the adapters can be removed from the body of the housing after the stainless steel clips have been removed from the housing. Before reinstalling, it should be ensured that both the adapter with the O-ring and the sealing surface in the body are clean and undamaged. The adapters should be fitted carefully in the housing (it is best to turn them), so that the O-ring is not damaged. With this flow sensor, there is no need for run-in and run-out sections. However, it should be ensured that the flow sensor is at all times filled with medium. Any preferred installation position is possible, but the best possible venting position should be chosen (rotor axis horizontal, flow horizontal or from bottom to top).

Options :

- Transparent cover DN 10

- Air or gas model

Accessories :

- Cable/round plug connector (KB...) see additional information “Accessories”

- Evaluation electronics OMNI-TA

- Mechanical connection pieces with non-return valve, filter, constant flow device or customer-specific requirements available on request

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Sensor | inductive |

| Nominal width | DN 10 (RRI-010), DN 25 (RRI-025) |

| Pressure resistance | PN 16 bar |

| Medium temperature | 0..60 °C |

| Materials, nonmedium- contact | PVC cable, 1.4305, 1.4301, CW614N nickelled |

| Current consumption at rest | 10 mA / NAMUR max. 7 mA |

| Output current max. | 200 mA / NAMUR max. 7 mA |

| Electrical connection Sensor | cable 2 m or for round plug connector M12x1, 4-pole |

| Resistant to short circuits | yes |

| Reversal polarity protected | yes |

| Ingress protection | IP 67 |

| Conformity | CE |

| Make | Honsberg |

| Download |

Preferred Buyer From

| Location | Worldwide |

Flow Transmitter RRI :

- Uncomplicated measurement of flow rates

- No magnets; uses inductive sensor

- Long working life thanks to high quality ceramic axis and special plastic bearing

- Run-in and run-out sections are not necessary.

- Modular construction with various connection systems

- Plug-in and rotatable connections

- Output signal PNP or NPN

- Intrinsically safe behaviour

- Optionally, non-return valve, filter, constant flow rate device in the connections.

Characteristics : The flow meter consists of a spinner which is rotated by the flowing medium. The rotor's rotational speed is proportional to the flow volume per unit time. The rotor is fitted with stainless steel clamps (optionally titanium or Hastelloy. An inductive proximity switch records the rotational speed, which is proportional to the flow rate.

Wiring : the valve should be installed behind the sensor. A running up time of approx. 0.5 seconds and a running down time of approx. 3 seconds should be noted.

Handling and operation

The Rototron device is installed in the pipework with the aid of the rotatable adapter pieces. If necessary, the adapters can be removed from the body of the housing after the stainless steel clips have been removed from the housing. Before reinstalling, it should be ensured that both the adapter with the O-ring and the sealing surface in the body are clean and undamaged. The adapters should be fitted carefully in the housing (it is best to turn them), so that the O-ring is not damaged. With this flow sensor, there is no need for run-in and run-out sections. However, it should be ensured that the flow sensor is at all times filled with medium. Any preferred installation position is possible, but the best possible venting position should be chosen (rotor axis horizontal, flow horizontal or from bottom to top). Air bubbles affect the measurement results. For filling processes

Options : Rotor with titanium clamps

Accessories :

- Cable/round plug connector (KB...) see additional information “Accessories”

- Evaluation electronics OMNI-TA

- Mechanical connection pieces with non-return valve, filter, constant flow device or customer-specific requirements available on request

MOQ : 20 Piece

| Business Type | Exporter, Supplier |

| Make | Honsberg |

| Analog output | 4..20 mA or 0..10 V |

Preferred Buyer From

| Location | Worldwide |

Features:

- Flow transmitter with display

- For pipe diameters of DN32 or larger

- Plastic version

- Suitable for retrofitting in existing pipelines with tapping clamps

- Two programmable switches

- Selectable units in the display

- Parameter change via rotating ring

- Electronics housing with non-scratch, chemically resistant glass

- Rotatable electronic housing for best reading position

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Sensor | biased Hall sensor |

| Nominal width | DN 15..50 |

| Process connection | male thread G 1/2 A...G 2 A |

| Metering ranges | 1.8..1133 l/min |

| Measurement accuracy | ±1 % of full scale value in the specified metering range, including linearity and repeatability |

| Medium temperature | -20..+85 °C optionally -20..+150 °C (for 8 bar min.) |

| Ambient temperature | -20..+70 °C |

| Storage temperature | -20..+80 °C |

| Material electronics housing | CW614N nickelled |

| Max. particle size | 0.5 mm |

| Pressure loss | 0.3 bar at Qmax. |

| Pressure resistance | PN 250 bar |

| Supply voltage | 10..30 V DC |

| Current consumption | 20 mA without load |

| Max. load current | 100 mA |

| Electrical connection | for round plug connector M12x1, 4-pole |

| Ingress protection | IP 67 |

| Conformity | CE |

| Make | Honsberg |

| Download |

Preferred Buyer From

| Location | Worldwide |

Details :

- High precision

- No magnetic components in the flow space

- High pressure resistance

Characteristics :

- A turbine acts as the primary sensor; its rotational speed is proportional to the flow rate.

- The rotational speed is detected by means of a biased Hall sensors, i.e. there are no magnets in the flow space.

Handling and Operation :

Installation : As with all flow meters, if possible the turbine should be installed ahead of a valve (on the pressure side). Good degassing should be ensured. 10 x D calming sections are recommended before and after the turbine in order to maintain the specified accuracies. The turbine should be filled with fluid at all times. The electronics housing does not project into the flow space.

Options :

- Flanged model,

- max. temperature 150oC

- DN 80-300 PN 16

- model for air / gas

- range from 0.05 m³/h

Accessories :

- Cable/round plug connector (KB...)

- see additional information “Accessories”

- OMNI-TA

MOQ : 50 Piece

| Business Type | Exporter, Supplier |

| Sensor | gearwheel volumeter |

| Nominal width | DN 8..25 |

| Process connection | female thread G 1/4..G 1 |

| Metering ranges | 0.02..150 l/min |

| Measurement accuracy | ±3 % of the measured value in the specified metering range (measured at 20 mm²/s) |

| Repeatability | ±0,3 % |

| Medium temperature | -25..+80 °C |

| Ambient temperature | -20..+70 °C |

| Electrical connection | optional plug DIN 43650-A / ISO 4400 or for round plug connector M12x1, 4-pole |

| Ingress protection | IP 65 |

| Conformity | CE |

| Make | Honsberg |

| Download |

Preferred Buyer From

| Location | Worldwide |

Details :

- Ideally suited for viscous media (oils)

- Light and compact construction in an aluminium housing

- For cost-sensitive applications

Characteristics :

- The VHZ gearwheel flow meter measures the flow by a volumetric principle, in which a pair of gearwheels is moved proportional to the flow rate. The movement of the gearwheels is measured through the enclosing housing wall by a sensor.

- The devices are suitable for viscous, fluid, self-lubricating media, as well as for aqueous fluids such as soaps, pasts, emulsions etc. which have a non-abrasive character. Because of the volumetric functioning principle, the devices are almost completely independent of viscosity. A push-pull transistor output, an A / B output or a two wire output are available as signal output.

- The push-pull output can as desired be connected as a PNP or an NPN output, and emits a frequency proportional to the flow rate. The A / B output consists of two push-pull outputs, whose signals are phase-shifted by 90 °.

- This makes it possible to determine the direction of flow using the bidirectionally driven sensor. The 2 wire model represents the pulse as two different currents, and has the advantage of reduced wiring effort.

- Alternatively, it is possible to use add-on electronics with signal processing, in the series OMNI, FLEX and LABO.

Wiring : Before the electrical installation, it must be ensured that the supply voltage complies with the data sheet. The use of shielded cabling is recommended.

Handling and Operation

Installation : The VHZ flow measurement device can be installed anywhere in the pipework system. A run-in section is not required. The direction of flow may be freely chosen. It should be ensured that no dirt particles (thread cutting swarf!) can get into the flow space, as this could cause the blockage of the gearwheels. It may therefore be necessary to install filters upstream of the flow measurement device (mesh size 30 μm).

Options : Highest temperature 120oC

Accessories :

- Cable/round plug connector (KB...) see additional information “Accessories”

- Remote flow display OMNI-TA